Our Services - Sugar Syrup Filtration

Sugar Syrup Filtration

Sugar syrup used for soft drinks mainly is from cane sugar with 60° - 68° brix

and at a filtration temperature of 70° - 85°C. The quality of sugar differs widely

depending on its origin and refining process. In the beverage industry the

purity of the sugar solution is measured in ICUMSA or RBU units. A high

ICUMSA or RBU reading (150 - 450) indicates a poor quality sugar and means

it is difficult to process. The international accepted standard for sugar syrup

with 65° brix is less than 50 ICUMSA.

Sugar syrup used for soft drinks mainly is from cane sugar with 60° - 68° brix

and at a filtration temperature of 70° - 85°C. The quality of sugar differs widely

depending on its origin and refining process. In the beverage industry the

purity of the sugar solution is measured in ICUMSA or RBU units. A high

ICUMSA or RBU reading (150 - 450) indicates a poor quality sugar and means

it is difficult to process. The international accepted standard for sugar syrup

with 65° brix is less than 50 ICUMSA.

To reduce the ICUMSA/RBU value the

syrup often is treated with activated

carbon (AC) and hyflow supercell. The

AC dosages range from 0.2 to 0.8 %.

Because of the high dosage of AC,

filters with a

large sludge volume

should be used.

In cases where a

continuous filtration process is

required, it is advisable to use two

filters so that while one filter is

filtering, the second filter can be in

preparation or CIP.

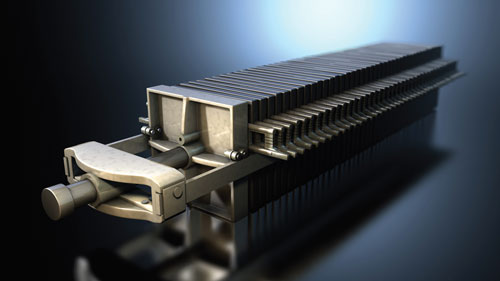

For the filtration of sugar syrup, excellent results are obtained with a ATPL

make Zero hold up Sparkler filter press or Vertical plate and frame filter press

whichever filteration capacity system is preferred. Both these filters are

designed to withstand high temperatures, leakproof, robust construction in

superior stainless steel.

Furthermore the filters are available either as manually operated plants or

with hydrulic control systems.

Zero hold up Sparkler filter press.

Compact skid mounted unit complete with Hyflow coating tank, syrup

cooling PHE, SS control panel, pipes and fittings.

Capacity range starting from 200 LPH to 3000 LPH.

Vertical plate and frame filter press

With or without hydraulic closing device.

Capacity range starting from 2000 LPH to 20,000 LPH